PRODUCT DESCRIPTION

HM Series Hammer mill

Excellent in industrial and laboratory applications

The hammer mill is suitable for milling and sizing products.

HM-300 has new design and technics which improve the efficiency and easy to clean and maintenance. Also support the inline/offline sterilization.

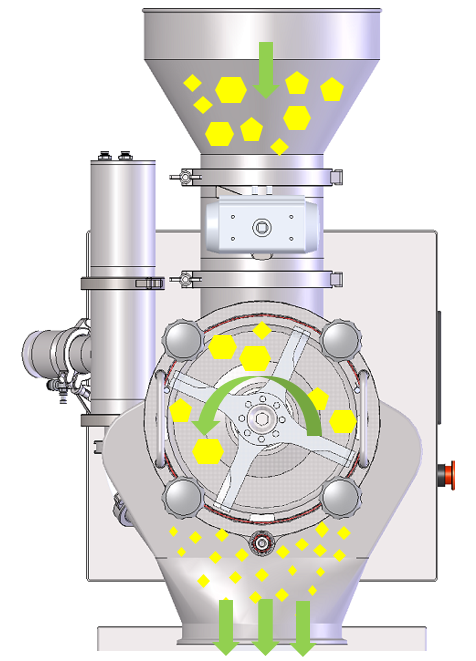

HM Series milling process

Advantages:

Ø Bigger active sieve surface lead to higher throughput and low temperature rise.

Ø The good design reduce the number of the moving parts. The connection of the tri-clamps assure an easy way to assemble and dismantle the milling chamber which assure the offline sterilization;

Ø This means: Quick and easy cleaning and maintenance and high operational availability at lower operating costs.

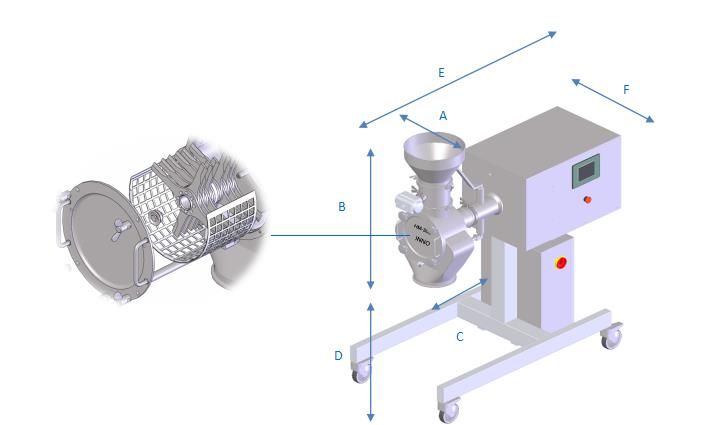

A. All tri-clamp assembled feeding device;

B. AT rotating cylinder;

C. The high speed rotor with both knife and hammer side;

D. The rotor and the sieve do not have mechanical contact;

E. High active opening sieve;

F. The milling head can be easily dismantled.

Function:

The product goes through the feeding valve which ensures a consistent product flow to the milling chamber. Then the product is impacted by the high speed rotor and then becomes smaller particles which goes down through a screen mounting below the rotor. Customer can adjust the rotor speed and screen size to achieve required particle size distribution.

HM Series hammer mill Summary

HM Series hammer mill summary

Ø The milling chamber can be dismantled via a tri-clamp;

Ø The safety switch does not have cable outside;

Ø The half round screen has as high as 40% active opening;

Ø Easy to clean, no outside cable;

Ø Easy assembly;

Ø Easy access of operation;

Ø The smallest milling size is 30um.

| Dimensions | A | B | C | D | E | F |

| HM-300 | 320 | 865 | 445 | 740 | 1440 | 750 |

| HM-400 | 320 | 1035 | 473 | 660 | 1488 | 750 |

Advantages

Ergonomic and easy to use

Ø Modular, compact design

Ø Easily change rotor and screen

Ø Mobile support stand

Ø Lightweight, detachable milling head

Ø The "Error Proof System" guarantees correct installation and removal of the rotor and screen.

Cleaning according to the strictest health standards

Ø Milling head can resist steam sterilization under pressure 2.2 bar;

Ø The milling head is made from stainless steel 316L. The polished, even surfaces allow the product to flow through without friction and without leaving residues;

Ø HM-300 supports WIP and CIP;

Ø No outside cable make cleaning easier and quicker.

HM Series hammer mill details

| Execution | Parts in contact with products | Parts not in contact with products |

| Metal | Stainless steel 316/316L | Stainless steel 304 |

| Seals | FDA compliant plastic(EPDM/PTFE) | Various plastics |

| Surfaces | Ra<0.4, polished | Ra<0.8, polished |

| Weld seams | Ground and polished | Brushed and treated |

| Rotor | Depending on products, rotor side and hammer side can be chosen | |

| Screen | Square opening, size from 0.1mm to 10mm | |

| Distance of screen and rotor | No mechanical contact | |

HM Series hammer mill performance

Better performance

Ø HM-300 has bigger active screen opening, about 30% larger than the competitors;

Ø Higher throughput;

Ø The height of the machine is adjustable;

Ø The dead surface of the sieve is very small and there is therefore no danger of the product overheating

| Type | Throughput | Voltage | Speed | power | weight |

| HM-300 | 50~1200kg/h | 380V-50Hz | Max 6000rpm | 4.0kw | ~250kg |

| HM-400 | 50~2400kg/h | 380V-50Hz | Max 4500rpm | 7.5kw | ~300kg |

*The throughput and final PSD is decided by material characteristics. The following is performance of the machine regarding to some products for reference:

| Product name | Particle size | Throughput (kg/h) |

| Vitamin C | 100 mesh/150 um | 500 |

| Sugar | 100 mesh/150 um | 500 |

| Salt | 100 mesh/150 um | 400 |

| Ketoprofen | 100 mesh/150 um | 300 |

| Carbamazepine | 100 mesh/150 um | 300 |

| Metformin hydrochloride | 200 mesh/75 um | 240 |

| Anhydrous sodium carbonate | 200 mesh75 um | 400 |

| Cefmenoxime hydrochloride | 300 mesh/50 um | 200 |

| Amino acid mixture | 150 mesh/100 um | 350 |

| Cefminox sodium | 200 mesh75um | 300 |

| Levofloxacin | 300 mesh/50 um | 250 |

| Sorbitol | 80 mesh/200 um | 180 |

| Hydrochloric acid to whalen | 200 mesh75 um | 100 |

| Clozapine | 100 mesh/150 um | 400 |

| Sorbitol | 100 mesh/150 um | 300 |

| Cefuroxime sodium | 80 mesh/150 um | 250 |

Copyright © ZHUCHENG BAOZHIFENG MACHINERY CO., LTD. All Rights Reserved |

Sitemap

|

Powered by